A team of researchers from RMIT University, the University of Sydney, Hong Kong Polytechnic University, and Hexagon Manufacturing Intelligence in Melbourne has achieved a significant breakthrough in titanium alloys.

By integrating alloy design and 3D printing, they have developed a new type of titanium alloy that demonstrates remarkable strength without becoming brittle under tension.

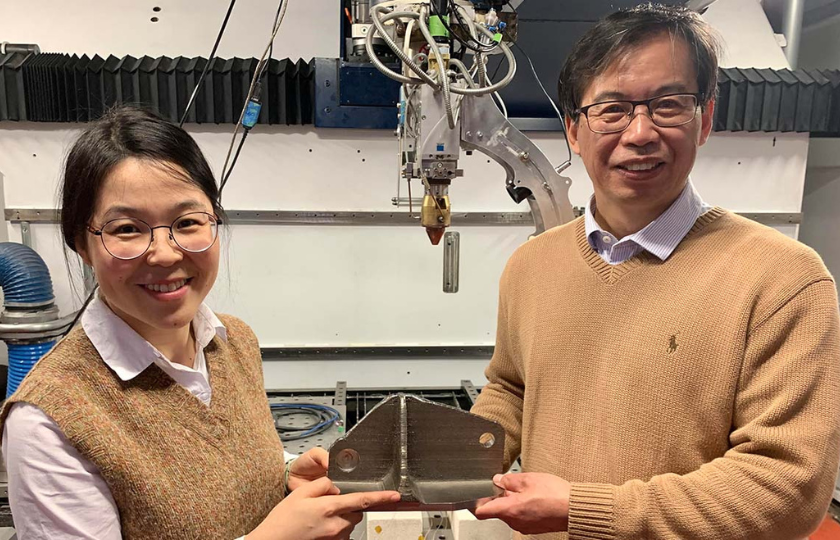

Lead researcher, Professor Ma Qian from RMIT said the team applied circular economy thinking to their design, to transform industrial waste and low-grade materials into valuable titanium alloys.

“Reusing waste and low-quality materials has the potential to add economic value and reduce the high carbon footprint of the titanium industry,” said Qian

Traditional titanium alloys have relied on the addition of aluminium and vanadium. In this study, the researchers explored the use of oxygen and iron as both abundant and inexpensive stabilisers.

However, Quian explained that there are two challenges in its development: first, oxygen can make titanium brittle, and second, adding iron can lead to serious defects.

Qian said those challenges have hindered the development of strong and ductile alpha-beta titanium-oxygen-iron alloys through conventional manufacturing processes.

“A key enabler for us was the combination of our alloy design concepts with 3D-printing process design, which has identified a range of alloys that are strong, ductile and easy to print,” he added.

To overcome these challenges, the team employed Laser Directed Energy Deposition (L-DED), a 3D printing process capable of creating large and intricate metal parts.

Combining their innovative alloy design concepts with the advantages of 3D printing enabled the researchers to produce a range of titanium alloys that are strong, ductile, and easily printable.

In addition, the newly developed titanium holds promise for various applications in aerospace, biomedical, chemical engineering, space, and energy technologies.

These alloys offer potential economic value while significantly reducing the carbon footprint associated with the titanium industry.