Scientists from the University of South Wales (UNSW) have discovered a process that allows 3D-printed plastic to heal itself using only light and the inclusion of a “special powder” at room temperature.

According to Professor Cyrille Boyer and his team, Dr Michael Zang and Dr Nathaniel Corrigan, the addition of a powder additive, trithiocarbonate, to the liquid resin used in the printing process can offer immediate repairs should the plastic break.

The scientists say the process makes the repaired plastic even stronger than before it was damaged. In addition, it increases the lifespan of the material because the broken parts would not need to be discarded or even recycled – potentially reducing plastic waste.

“In many places where you use a polymer material, you can use this technology,” said Dr Corrigan. “So, if a component fails, you can repair the material without having to throw it away.”

Trithiocarbonate was originally developed by the Commonwealth Scientific and Industrial Research Organisation (CSIRO) as a reversible addition-fragmentation chain transfer (RAFT) agent that allows rearrangement of nanoscopic particles make up the material and allows broken pieces to re-fuse.

The damaged product only needs to be directly placed under UV LED lights for approximately one hour, which causes a chemical reaction and repair the broken pieces.

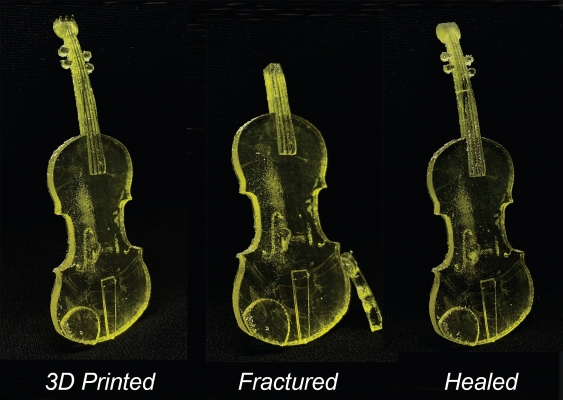

Experiments, including on a 3D-printed violin, has shown that the self-repairing plastic is fully healed comparable to its original unbroken state.

He also added that other processes that involve self-healing 3D plastics usually requires 24 hours and multiple heating cycles, while theirs only take an hour under regular light.

“With our system, you can leave the broken plastic in place and shine the light on the entire component. Only the additives at the surface of the material are affected, so it’s easier and also speeds up the entire process,” Dr Corrigan explained.

The new technology could potentially be used in a range of commercial applications where 3D printed materials are currently used, including wearable electronics, sensors, and even footwear manufacturing.

The results of the team’s research have now been published in the journal Angewandte Chemie International Edition.