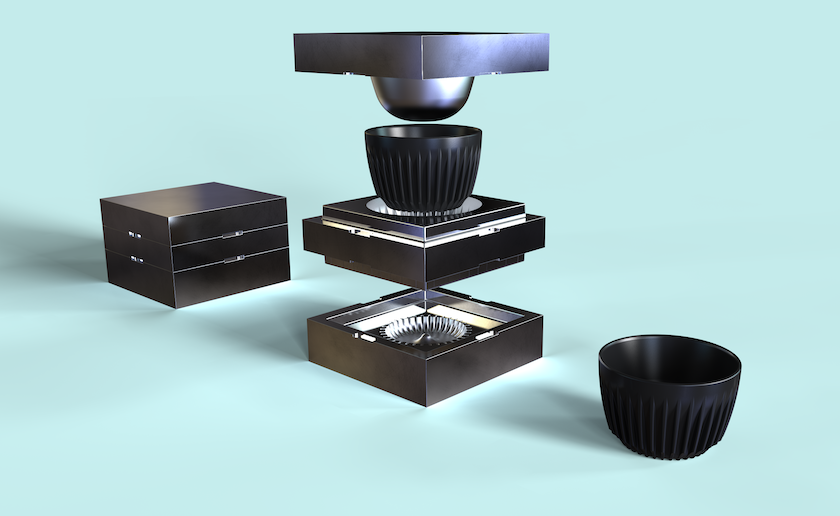

Advanced 3D technology has helped Sydney studio Vert Design convert waste coffee husks into an award-winning reusable coffee cup, dubbed the HuskeeCup.

Working backwards, the team designed and developed a product specifically to generate economic demand for waste.

Sustainability is at the core of all Vert Design’s practices – it’s even in the studio’s name: vert is French for green.

Founder and director Andrew Simpson says the team is always up for the challenge of designing for sustainability.

“The process is often difficult, complicated, and requires a lot of trial and error. But it’s something we care about passionately, so we believe it’s worth doing and worth doing well,” he said.

The HuskeeCup embodies the studio’s core sustainability values. A firm believer in experimentation, Simpson’s team has time and again come up with innovative approaches to tackling sustainable design.

A key approach for the company is taking a holistic view in analysing a product’s entire lifecycle. By doing this, the team identifies opportunities to set new foundations for an economy that helps address the core of any environmental impacts a product may have.

“The reality is that there are no sustainable materials, so we should always find the ones that have the lowest impact. All materials consume energy in their production and they generate waste. We look at the whole lifecycle – the transportation, the production, usage and end-of-life then recycling and then that loop goes back to the beginning,” said Andrew.

The team was able to design and develop a range of coffee cups made from waste coffee husks mixed with eco-polymers with the help of Dassault Systèmes Solidworks – a cutting edge 3D computer-aided design and engineering software.

“Our initial approach was inspired by a unique thought. If we could find adaptive reuse for waste products and we have the innate ability of design to generate demand, why not use that ability to generate a demand for waste?,” Simpson explains.

He says the HuskeeCup’s striking and memorable design would not have been possible a few decades ago as limitations in technology meant an industrial designer had to self-edit to create a more controllable form.

The 3D design software’s capabilities meant the team was able to take more technical risks while designing, which allowed them to manipulate the cup’s form while still ensuring it was manufacturable. The improved surface modelling and flexibility in control within the system also allowed the team to create and explore surface decoration in a way that wouldn’t have been possible or achievable only a few years ago.

“Our studio is really based on experimentation in the prototyping process,” shared Mitchell Brown, a senior designer within the team. “We wanted to test that this organic material could actually be moulded into the cup form, so we used the tools within the software to build prototype moulds and we tested it in our studio.”

This process helped the team calculate and test the product’s risks before it reached the production level.

“There’s a whole bunch of thinking in design that’s not based in language and using the act of drawing informs better ideas to visually and technically solve problems, or to capture and explore different opportunities that exist within something,” said Simpson.

Brown adds that technological improvements have helped streamline the team’s end-to-end design processes. Where they previously had to work across multiple types of software, they’ve now seen huge benefits from using a single platform to deliver a product design from start to finish.

For Brown, having the feature history in one place on Dassault Systèmes Solidworks was the biggest winner.

“This builds into how we structure our design practice. We present concepts and then if we get feedback, the ability to directly edit original concepts through that feature tree is a real time saver. That’s been the biggest improvement we’ve seen over the years,” Brown said.

As a consultancy, any tool which helps the team save time and work more efficiently brings value to their work and ultimately to their customers.

“We want to produce the best design outcomes, but we also want to produce the most efficient design outcomes because that affects the cost and value we can offer,” he said.

- Converting coffee husks into a keep cup is not the only repurposing of waste Viable.Earth has written about recently. Krill Design converts orange peel into table lamps.