The fashion industry has been grappling with the issue of textile waste for a long time now. The linear take-make-dispose model has caused a significant environmental impact, and sustainable alternative textiles are being sought.

One of the most popular fabrics used in high-end fashion is silk. However, silk production is less sustainable than one might think. Despite being one of the most ancient and luxurious textile fibres, silk production involves a lot of resources and chemicals, contributing to environmental degradation.

“Fashion designers love to use silk,” said Thomaine Dolan Dow, director of materials innovation and design at MII (Materials Innovation Initiative). “It’s one of the most luxurious and ancient textile fibres, and silk’s smooth, continuous filament gives silk yarn unique properties such as strength, elasticity, and resistance to pilling.”

With rising concerns for sustainability and the environment, material innovators are redefining sustainable textiles.

The report from MII highlights several such innovators who are working on creating new sustainable silk fabrics that have minimal environmental impact without compromising on the material’s positive attributes.

12 material innovators redefining sustainable textiles

Amsilk

Innovation: Fermentation

Established: 2008

Country: Germany

Description: Amsilk’s Biosteel fibre is a high-performance filament fibre made of spider silk protein produced by genetically engineered microbes and spun into fibre. It is a thinner and more delicate, biodegradable material than traditional animal-based silk. Amsilk’s material is hypoallergenic, bacteriostatic, and contains no petrochemicals. It can be used in various applications, from silk-like fabric to advanced materials like composites or sports shoes. It is also used in medical applications to coat breast implants and reduce postoperative complications.

Circ

Innovation: Textile-to-Textile Recycling

Established: 2011

Country: USA (Virginia)

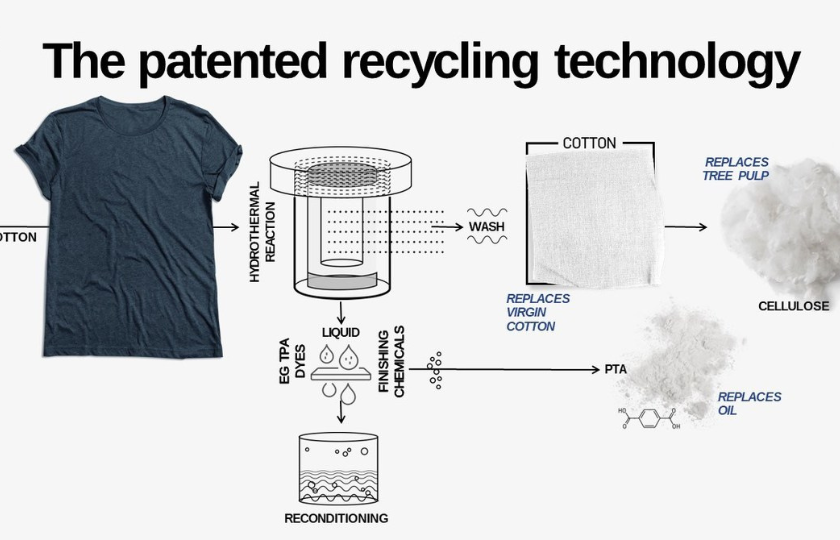

Description: Circ has developed a proprietary hydrothermal process to recycle polyester-cotton blended textiles and recover the polyester and cotton portions to create like-new fibres for sustainable textiles. In addition to this, Circ also regenerates cellulose from the cotton portion of polycotton textile waste to create Circ Lyocell.

Eastman Naia

Innovation: Cellulosics

Established: 1920

Country: USA (Tennessee)

Description: Eastman Naia is a sustainable textile company that uses cellulosic fibres to create filament yarn and staple fibres. Its material is biodegradable, compostable, and compatible with molecular recycling. It is produced using low-impact manufacturing processes and environmentally sound chemicals sourced from sustainably managed forests. Naia has a smooth and silky-soft hand feel with a drape that can be made in lustrous or matte finishes and takes colour easily. Naia Renew, its latest offering, is made from 60 per cent cellulosic and 40 per cent certified recycled waste materials.

Ettitude

Innovation: Clean Bamboo woven material

Established: 2014

Country: USA (California)

Description: Ettitude’s Clean Bamboo woven material has a refined silken hand and surface sheen with high thread counts. It offers thermal temperature regulation, hypoallergenic and anti-fungal properties, and biostatic and deodorising.

Kintra Fibers

Innovation: Biosynthetics

Established: 2018

Country: USA (Headquartered in NYC)

Description: Kintra Fibers has developed a revolutionary bio-synthetic material that is 100 per cent bio-based and biodegradable. The material is made from fermented glucose and is compatible with standard polyester production equipment. The team can fine-tune their resin and yarn, making yarns applicable to a wide range of knit and woven sustainable textiles.

Kintra’s brand and mill pilot partners already use their yarns as an alternative to traditional synthetic PET polyester and Nylon. They have created fabrics that are suitable for applications traditionally made with animal-based fibres, including a satin woven with a silk-like hand feel and a knit with a cashmere-like hand feel.

Lenzing

Innovation: Cellulosics

Established: In 1892 as a pulp and paper mill; added fibre and raw material in the 1940s

Country: Austria

Description: Lenzing uses sustainably sourced and harvested trees to produce wood pulp and cellulosic fibres. Its flagship textile brand is Tencel, which is smooth, soft, and lustrous and has a beautiful drape. The company also offer other cellulosic products, such as EcoVero, which has a much lower environmental impact than generic viscose and is sourced from sustainably harvested wood pulp. Lenzing fibres are biodegradable in various conditions and certified by Canopy, the EU Ecolabel, FSC, and PEFC.

Nanollose

Innovation: Cellulosics

Established: 2011

Country: Australia

Description: Nanollose is a company that has created a cellulosic material called “Nullarbor” without using trees, arable land, or the associated use of irrigation, pesticides, and other resource-intensive inputs.

The material is made mainly from waste coconut water from the food and beverage industry using a fermentation process similar to converting wine to vinegar. The resulting fibre and fabrics behave like conventional lyocells but are significantly stronger than lyocells made from trees. It can be hand or machine-washed and is available in several iterations, including a silky single jersey and a fine woven.

Since its establishment, the company have produced half a ton of fibre and has successfully converted it into yarns, fabrics, and garments.

Orange Fiber

Innovation: Cellulosics

Established: 2014

Country: Italy

Description: Orange Fiber offers circular fabrics made from citrus fruit waste. Its patented method extracts cellulose from citrus waste and chemically processes it into acetylated cellulose fibres, which can be blended with other sustainable fibres. The fabrics can be customised to be matte or shiny and dyed, coloured, or printed. In 2021, Orange Fiber partnered with the Lenzing Group to turn their citrus pulp into the first Tencel-branded Lyocell fibre.

Renewcell

Innovation: Recycling

Established: 2012

Country: Sweden

Description: Renewcell uses recycling technology to break down used cotton and other cellulose-rich textiles and transform them into a new biodegradable raw material called Circulose pulp, which can be used to make biodegradable virgin quality viscose, lyocell, modal, acetate, and other kinds of sustainable textiles.

Rubi Laboratories

Innovation: Cellulosics

Established: 2021

Country: USA (California)

Description: Rubi Laboratories focuses on creating sustainable solutions for the fashion industry. A cell-free enzymatic process converts CO2 into pure cellulosic pulp, which is then spun it into fibres via wet spinning. The process allows them to create a lyocell yarn suitable for apparel production, all while producing zero CO2 waste.

Spiber Inc

Innovation: Brewed Protein synthetic protein materials

Established: 2007

Country: Japan

Description: Spiber Inc is a biotechnology company that has developed Brewed Protein, a synthetic protein material that can replace silk and other animal fibres and petroleum-based plastic fibres.

Desired protein codes are inserted into microorganisms, which grow in a bioreactor, and after fermentation, the protein is purified and dried into a pellet or powder.

The Brewed Protein polymer can be made into fibre, films, or material, primarily focused on textile applications for the apparel industry. The material also emits fewer GHGs, requires less water, reduces land use, biodegrades in marine environments and disintegrates in soil.

Tandem Repeat

Innovation: Squitex protein-based filament fibre

Established: 2017

Country: USA (Pennsylvania)

Description: Tandem Repeat developed Squitex, a protein-based filament fibre, using precision fermentation technology to create powders, fibres, yarns, and fabric. Squitex provides unique properties such as self-healing, elasticity, strength, and thermal responsiveness and can be processed through most current manufacturing equipment.

The company is also exploring the potential of plant molecular farming to produce Squitex fibres cost-effectively and environmentally friendly.